Medical Nitinol wire for guide wire

The ingredients are strictly subdivided to reduce the phase change temperature fluctuation, so that the performance of the material and equipment is more consistent

As one of the key indicators of superelasticity of nickel-titanium alloys, the actual action Af temperature is often used to evaluate the effective performance of superelasticity. ASTM F2063-18 stipulates that the nickel content is 54.5~57.0mass%, but because the actual action Af temperature is very sensitive to the composition, it is extremely important to subdivide the composition of the nickel-titanium alloy. Therefore, AprilTi uses the subdivision alloy code to identify the alloy.

| Alloy Code | A | B | S | C | D | E | J | K | L |

| Actual action temperature after heat treatment ℃ | 70+/-10 | 30+/-10 | 25+/-5 | 17+/-7 | 10+/-7 | 0-15 | +30+/-10 | 30+/-10 | -20+/-15 |

Delivery status:

Straightening the hyperelastic state (SE)

Cold-worked condition (CW), requiring subsequent heat treatment

Wire shape:

Nitinol round wire

Nickel-titanium flat wire, square wire

Nickel Titanium Rope

Wire surface state:

Oxidation state of black surface

bright state

Features:

High-quality NiTi alloy material: has good straightness and flexibility, and is not easy to bend; provides good torsional force, push force and control ability; better guidance, realizes 1:1 transfer of torsion, and has better lubrication Sex, reduce friction, improve the flexibility of operation, soft and gentle, reduce tissue damage of patients.

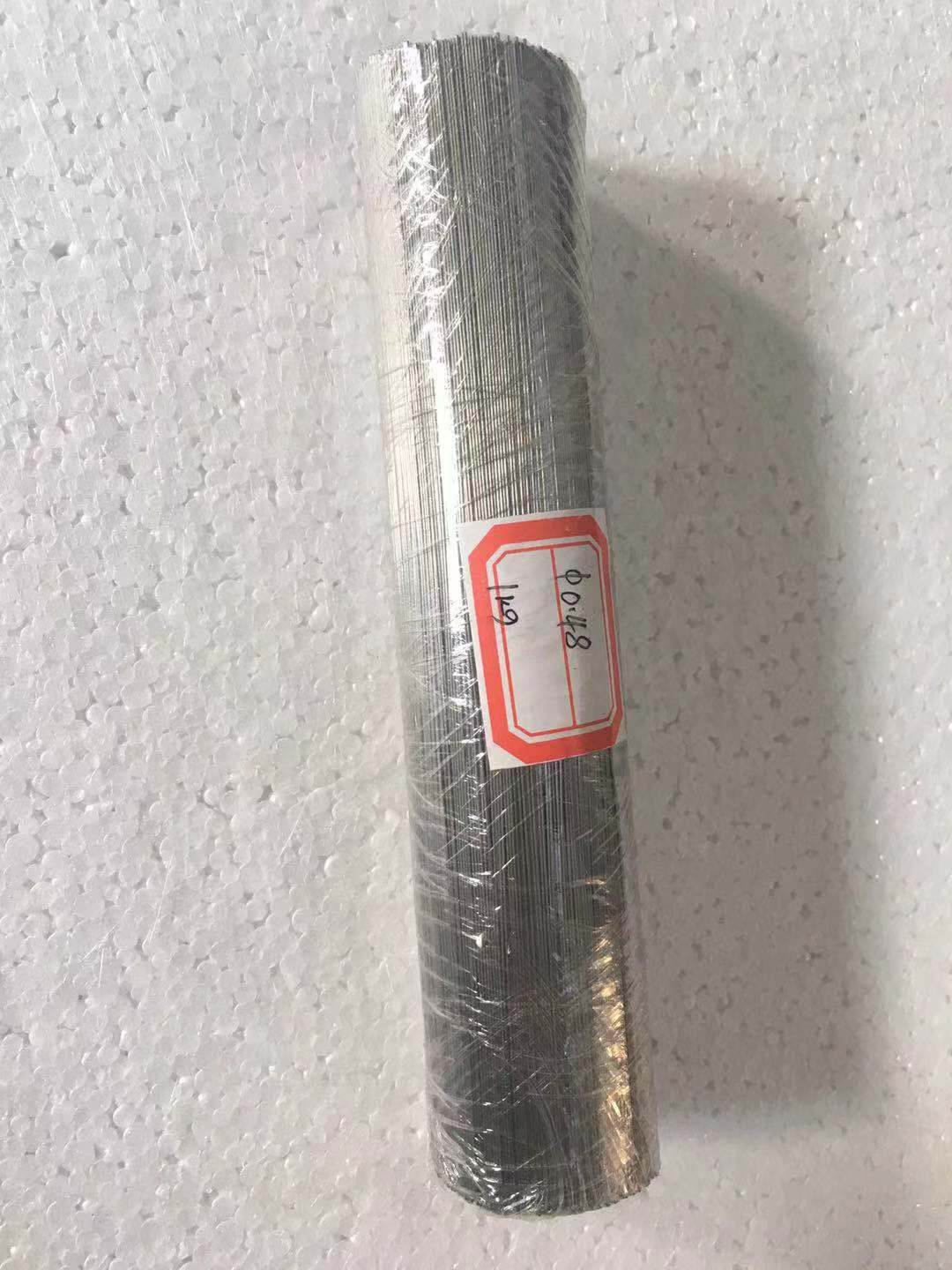

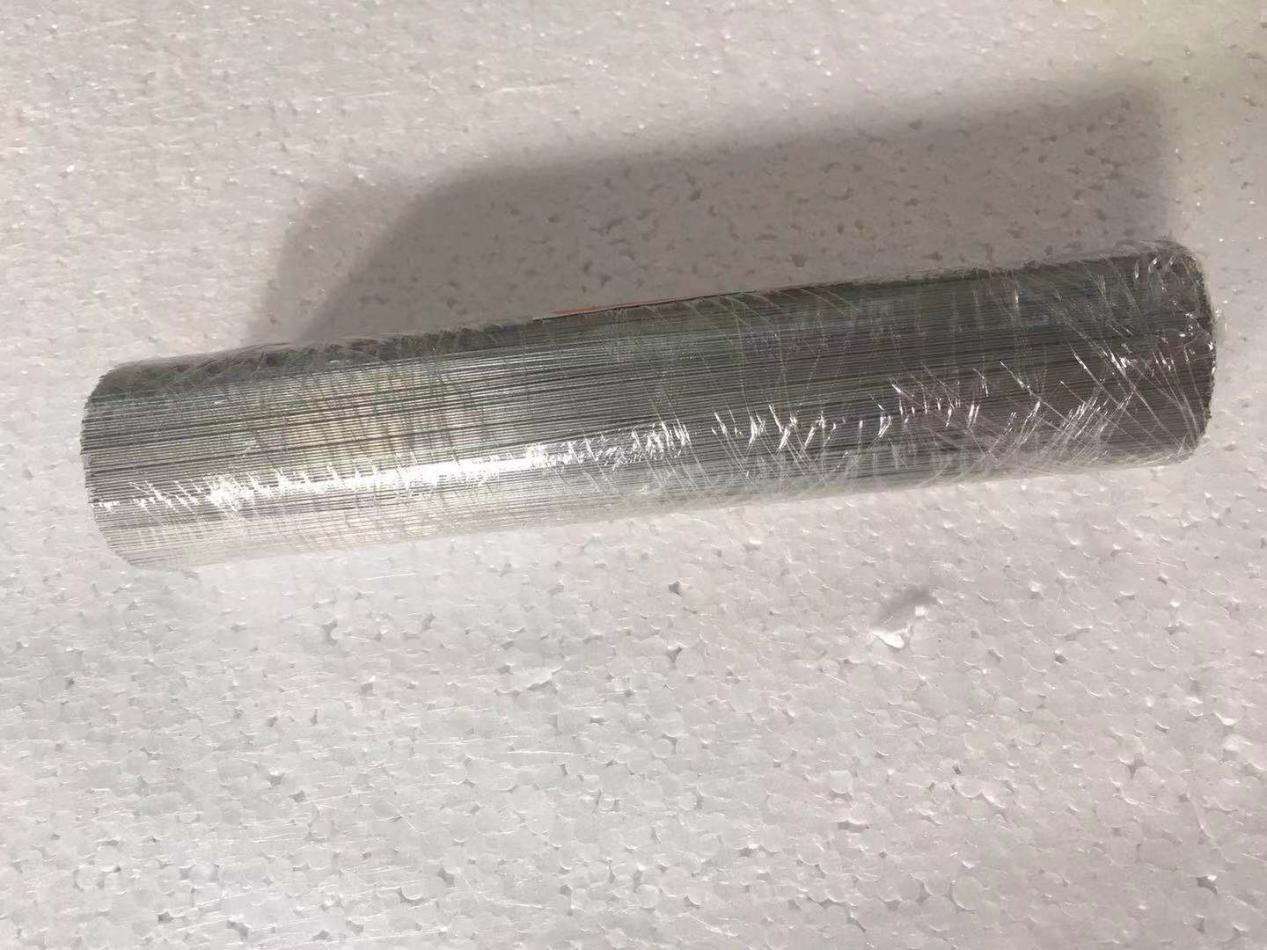

Detailed images of nitinol wire:

| Dimension and tolerance | Physical properties | |||

| Upper platform stress (Mpa) | Tensile strength (Mpa) | Elongation% | ||

| 2.000mm ~ 4.00mm | +/-0.02mm | ≥400 | ≥1000 | ≥10 |

| 1.500mm ~ 2.00mm | +/-0.01mm | ≥450 | ≥1200 | ≥10 |

| 1.000mm ~ 1.50mm | +/-0.01mm | ≥480 | ≥1300 | ≥10 |

| 0.350mm ~ 1.00mm | +/-0.007mm | ≥480 | ≥1300 | ≥10 |

| 0.260mm ~ 0.35mm | +/-0.007mm | ≥480 | ≥1300 | ≥10 |

| 0.150mm ~ 0.26mm | +/-0.005mm | ≥480 | ≥1300 | ≥10 |

| 0.080mm ~ 0.15mm | +/-0.004mm | ≥480 | ≥1300 | ≥10 |

| 0.050mm ~ 0.08mm | +/-0.003mm | ≥480 | ≥1300 | ≥10 |

| 0.013mm ~ 0.05mm | +/-0.002mm | ≥480 | ≥1300 | ≥10 |