Titanium target/Titanium sputtering target

Titanium sputtering target/Titanium target, titanium element symbol Ti, atomic number 22, density 4.45g/Cm3, physical properties: melting point 1668°C, boiling point 3262°C, specific heat capacity 0.52 (J / (Kg K), heat of evaporation 421 (KJ/Mol), The heat of fusion is 15.45 (KJ/Mol), and the electrical conductivity is 0.0234 (106/Cm). Since high-purity titanium sputtering targets are mainly used as getter materials in semiconductor materials and ultra-high vacuum devices, PVD coating. High-purity titanium has the ability to absorb Gas, especially hydrogen, CH4, Co2 gas, so it can be widely used in high vacuum and ultra-high vacuum systems. When using high-purity titanium sputtering to make LSI, VLSI, ULSI circuit networks, these can be integrated Parts become extremely light, thin, small in size and dense in wiring. High-purity titanium targets can also be used as barrier metal materials

Product name: Titanium Sputtering Target for PVD coating

Materail: Pure Titanium Gr2, titanium alloy Gr5 , Ti-Al , Ti-Cr, Ti-Zr etc.

Other material: Chrome, Zirconium , Copper , tungsten etc.

Shape: Round

Dimensions: 60/65/70/80/85/90/95/100(D)*height 30/32/35/40/42/45/50(T) ,can be customized

Color: Silvery, Metallic

Technology: Vacuum Melting

Origin: China Manufacturer

Application: Coating industry, sputtering vacuum coating industry

Detailed images:

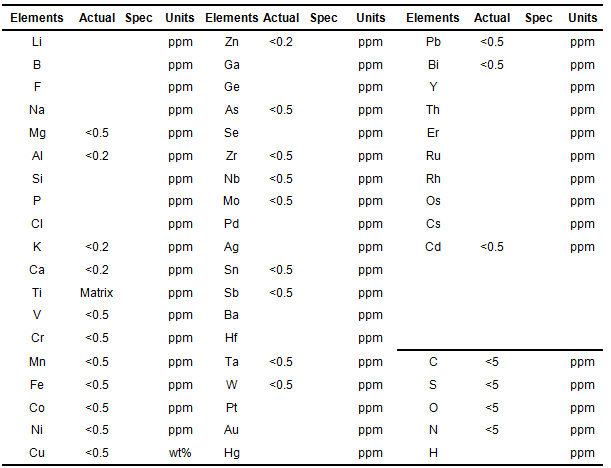

We produce high-purity sputtering targets whose most important benefits are thin films with excellent electrical conductivity and minimized particles during physical vapor deposition. The following table is the composition analysis certificate of high-purity titanium sputtering target. Analysis methods used:

- Use GDMS or ICP-OES to analyze metal elements;

- Use LECO to analyze gas elements.

Packing:

Packing:

Standard export packing. Plywood case outside